Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Sunson GA150L

Brand: SUNSON

Types Of: Enzyme Preparations

Place Of Origin: China

Packaging: 1KG;25KG

Productivity: 10000T/MONTH

Transportation: Ocean,Land,Air,Express,Express

Place of Origin: China

Supply Ability: 10000T/MONTH

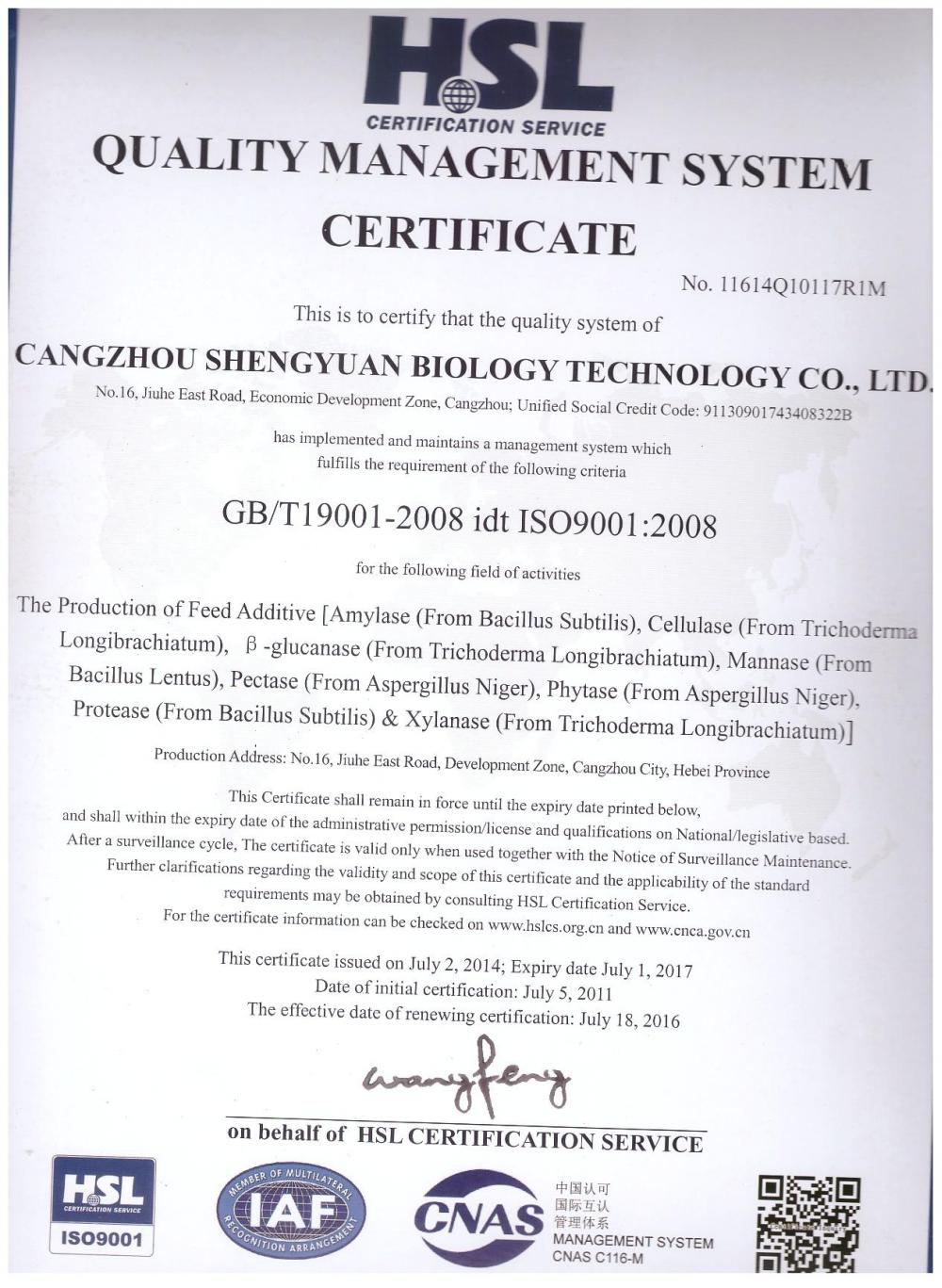

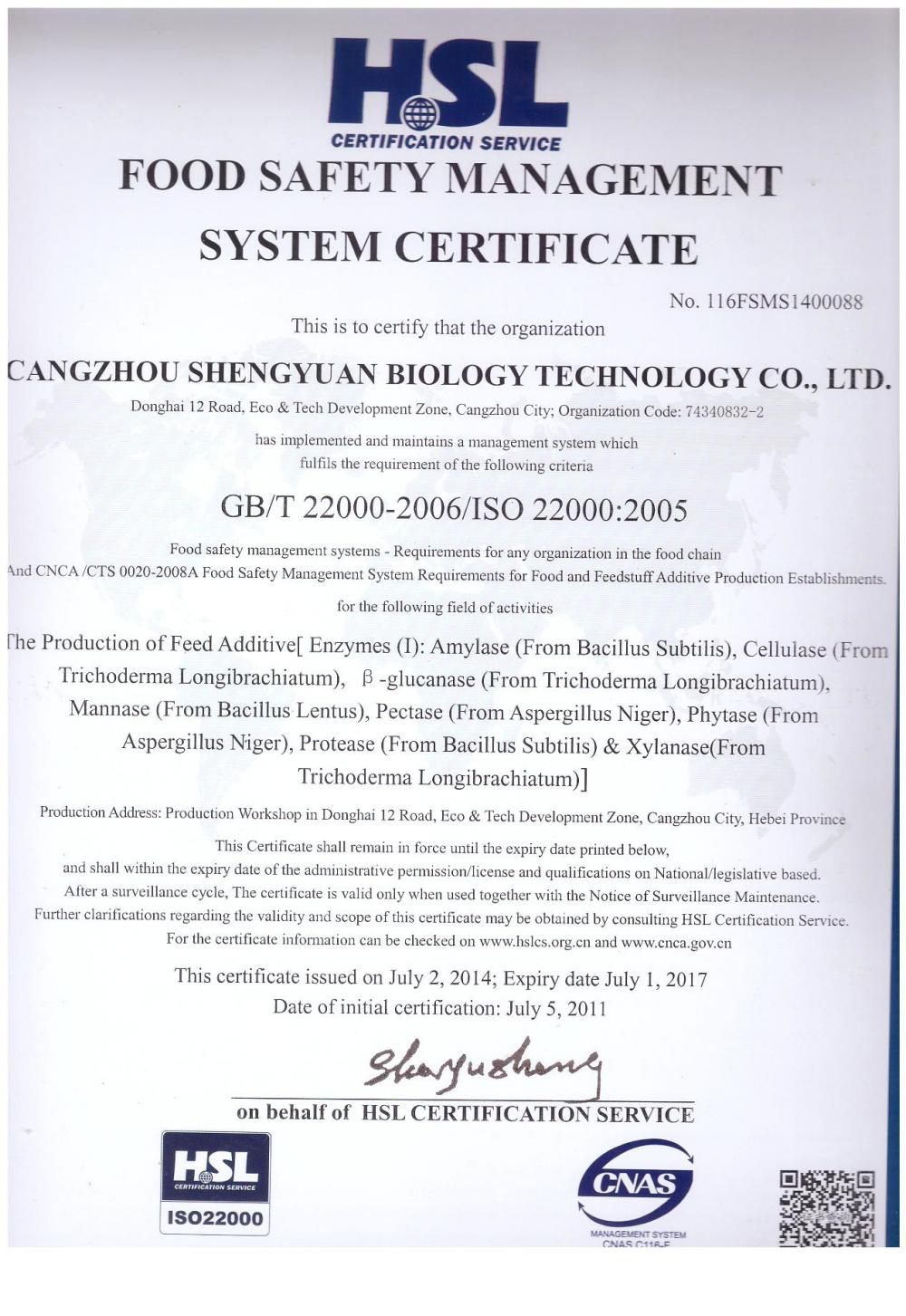

Certificate: ISO22000;MUI,FAMI-QS;NON-GMO;FSSC22000;KOSHER;HALAL

HS Code: 3507909090

Port: Tianjin,Shanghai,Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB

INTRODUCTION

glucoamylase (Glucan 1,4-α-glucosidase) is made from Aspergillus niger Produced by submerged fermentation, separation and extraction technology.1 unit of Glucoamylase equals to the amount of enzyme which hydrolyzes soluble starch to get 1mg glucose at 40℃ and pH4.6 in 1h.

Characteristics

| Declared Activity | 150000 u/g |

| Production Organism | Aspergillus niger |

| Physical Form | Liquid |

| Color | Brown ,Color can vary from batch to batch. Color intensity is not an indication of enzyme activity |

| Odour | Normal microbial fermentation odour. |

SPECIFICATIONS

| ITEMS | Lower Limit | Upper Limit |

| enymes activity | 150000u/g | |

| Lead | | 5 mg/kg |

| Arsenic | | 3 mg/kg |

| Total viable count | | 50,000 CFU/g |

| Coliform Bacteria | | 30 CFU/g |

| Escherichia coli | | 10 CFU/g 3 MPN/g |

| Salmonella | Not Detected/25g | |

Alcohol and ethanol industry: The recommended dosage is 0.6-1.0L per ton of total raw materials. Added at the beginning of saccharification after pH adjustment, then saccharifying at 60℃ and pH 4.0-4.5 for 30-60 minutes.

Beer industry: The recommended dosage is 0.4-0.8L of the enzyme preparation per ton of total raw materials, added at mashing-in.

Starch sugar industry: The recommended dosage is 0.5-1.0L per ton of dry starch when saccharifying at 60-63℃ and pH 4.3-4.5.

Other industries: Glucoamylase can also be used in the processing of rice wine, edible vinegar, antibiotic and citric acid industry, etc.

Packaging specification: 25kgs/drum; 1,125kgs/drum or as your request.

Storage

| Best Before | When stored as recommended, the product is best used within 6 months from date of delivery. |

| Shelf Life | 6 months at 25℃, activity remain ≥90%. Increase dosage after shelf life. |

| Storage Conditions | This product should be stored in a cool and dry place in sealed container, avoiding insolation, high temperature and damp. The product has been formulated for optimal stability. Extended storage or adverse conditions such as higher temperature or higher humidity may lead to a higher dosage requirement. |

Enzyme preparations are proteins, which may induce sensitization and cause allergic type reactions in sensitized individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa, so any direct contiguity with human body should be avoided. If irritation or allergic response for skin or eyes develops, consult a doctor.

Product Categories : Ethanol & Fermentation Enzymes

Sunson

Officially established in 1996, SUNSON Industry Group Co., Ltd. is a full functioning enzyme company covering R&D, production and sales. Headquartered in Beijing, SUNSON has 9 business divisions,1 Strain R&D Center, 1 Application Technology Center, 1 Technical Service Center and 1 Production Technology Center. Over more than 20 years Sunson has successfully developed series of innovative products widely applied in Feed, Brewing, Baking, Plant Extract, Leather, Alcohol, Textile, and so on. Now Sunson has been well recognized in the industry for its remarkable R&D capability, production capacity and outstanding products.

SUNSON was honored as the Key Enterprise of China Enzyme Industry by China Fermentation Industry Association, and was the first enzyme manufacturer certified with ISO 22000 Food Safety Management System in China. It was also certified with KOSHER and HALAL, ECOCERT Organic Farming Europe, FSSC22000 Food Safety Management System, ISO9001 Quality Management System and FAMI-QS. Sunson’s products have been exported to more than 50 countries or regions and widely accepted by our customers worldwide.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.